Founded in 2019 by Amit Srivastava and Ankit Chauhan, InfyU LABS is a rising startup in the agritech industry, headquartered in Gandhinagar, Gujarat.

The startup is addressing one of agriculture’s most critical challenges, which is reducing wastage of perishable goods, through innovative, technology-driven solutions.

Perishable Product Wastage and Inefficient Testing

India, like many other countries, faces an enormous challenge when it comes to food security and wastage.

The nation loses around Rs 244 crore worth of food every day, primarily due to inefficiencies in the supply chain.

A substantial amount of wastage occurs during the quality inspection phase.

Traditional food testing methods involve destructive techniques, where a sample of fruits or vegetables is cut open or tested in labs, often rendering a large portion of the consignment unusable.

Further compounding the problem is the delay in obtaining test results.

Conventional methods can take anywhere from a few days to weeks, during which time the perishable goods may spoil, exacerbating the already significant wastage problem.

This makes the entire process costly, inefficient, and highly dependent on human intervention, which can lead to errors and discrepancies.

Non-Destructive Testing and IoT-Based Innovation

InfyU LABS aims to bridge this gap by offering non-destructive, IoT-powered solutions that provide instant quality assessments.

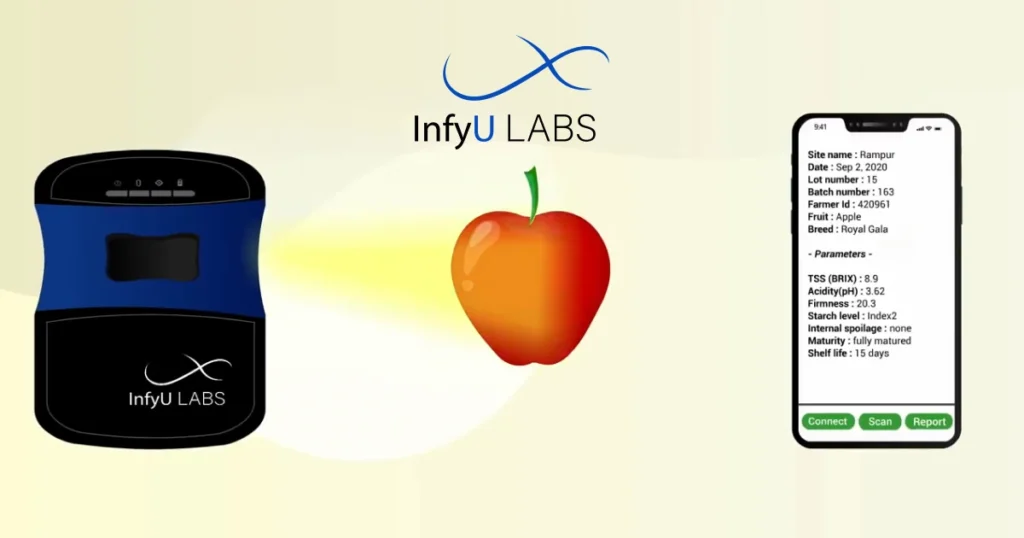

Their flagship product, Infyzer, is a portable device that can analyze fruits like apples, pomegranates, kiwis, and more within seconds.

It uses spectroscopy powered by machine learning algorithms to check various internal parameters such as TSS (Brix), acidity (pH), moisture content, starch index, firmness, shelf life, and ripeness, among others.

What sets Infyzer apart is that it does not require the expertise of trained lab technicians.

The device connects via Bluetooth to a smartphone app, where users can receive detailed quality reports instantly.

This means that farmers, aggregators, and retailers can make quick, informed decisions right at the source, eliminating the need for cumbersome lab testing.

Moreover, InfyU LABS has introduced InfyQR, a traceability solution that allows users to attach QR codes to consignments once quality-checked.

This feature enables real-time tracking of product quality across the supply chain, establishing transparency and trust between sellers and consumers.

Journey and Innovation

InfyU LABS began its journey with a vision to democratize food testing and improve food safety standards by using advanced technologies such as machine learning, deep learning, and IoT.

The company recognized that food testing was not only a logistical challenge but also a financial one.

Traditional lab setups require expensive infrastructure, trained personnel, and significant time investment.

By developing a handheld, cost-effective device that eliminates the need for complex infrastructure, InfyU LABS aims to make quality testing more accessible.

Their solutions focus on a broad range of fruits and vegetables that are difficult to assess based on appearance alone.

For example, fruits like kiwis or Alphonso mangoes maintain a consistent external texture, making it difficult for farmers and traders to judge quality based solely on visual inspection.

InfyU LABS’ technology analyzes the internal chemical composition of these fruits, offering more reliable and actionable data.

In addition to Infyzer, the company has rolled out PortaLabs, a service offering portable, easily accessible testing centers.

This gives farmers, retailers, and aggregators the option to test their products without investing in the Infyzer device itself, further lowering the barrier to entry.

Reducing Wastage and Enhancing Transparency

By introducing technology that allows for non-invasive testing, InfyU LABS significantly reduces the wastage that occurs during the quality inspection phase.

The device eliminates the need to destroy samples, preserves the freshness of the consignment, and provides near-instant results.

This also saves additional costs associated with transporting products to labs and minimizes human errors typically involved in manual testing.

The startup’s solutions are particularly beneficial to key players in the supply chain, such as aggregators and retailers.

Aggregators can use Infyzer to perform rapid quality checks on the spot when purchasing produce from farmers.

This ensures they only buy high-quality products, which in turn allows them to negotiate better prices when selling to downstream players.

Retailers, on the other hand, can benefit from the technology by ensuring they offer consumers fresh, high-quality products while minimizing disagreements.

InfyU LABS is also making strides in the export market, where Indian fruit exporters often face strict global quality standards.

The detailed quality reports generated by Infyzer can help exporters meet these stringent criteria, reducing the chances of rejection and ensuring that Indian produce is accepted globally.

A Promising Future for AgriTech

As the demand for high-quality, chemical-free produce grows worldwide, InfyU LABS is well-positioned to play a significant role in transforming how quality control is handled in the agricultural sector.

The company’s mission to “democratize food testing” is aligned with global trends that prioritize sustainability, traceability, and resource efficiency.

With their ongoing advancements in AI-driven analysis, cloud-connected technologies, and portable lab solutions, InfyU LABS is poised to reshape the agricultural landscape, not just in India but globally.

Their commitment to reducing food wastage and improving the overall supply chain efficiency makes them a key player to watch in the coming years.