Founded in 2017 by Aniruddha and Avra Banerjee, SwitchOn has emerged as a game-changer in the manufacturing sector, focusing on eliminating defects through artificial intelligence (AI) technology.

Based in Bengaluru, SwitchOn has set out on a mission to transform the quality inspection landscape, addressing long-standing challenges faced by manufacturers across various industries.

The Challenge: Defects in Manufacturing

The manufacturing sector is fraught with challenges related to quality control. Reports indicate that global manufacturers often allocate up to 25% of their workforce to quality inspection tasks.

Despite these efforts, many companies grapple with over 500 customer complaints per year per site, resulting in financial losses exceeding $12 million annually.

This paradox of investing heavily in quality assurance yet still facing substantial defect rates highlights a critical need for innovation.

SwitchOn’s founders recognized that traditional quality inspection methods were not only labor-intensive but also prone to inaccuracies, leading to costly rework and wastage.

In an era where speed and precision are paramount, the need for an automated, reliable solution became evident.

The Solution: AI-Powered Inspection Systems

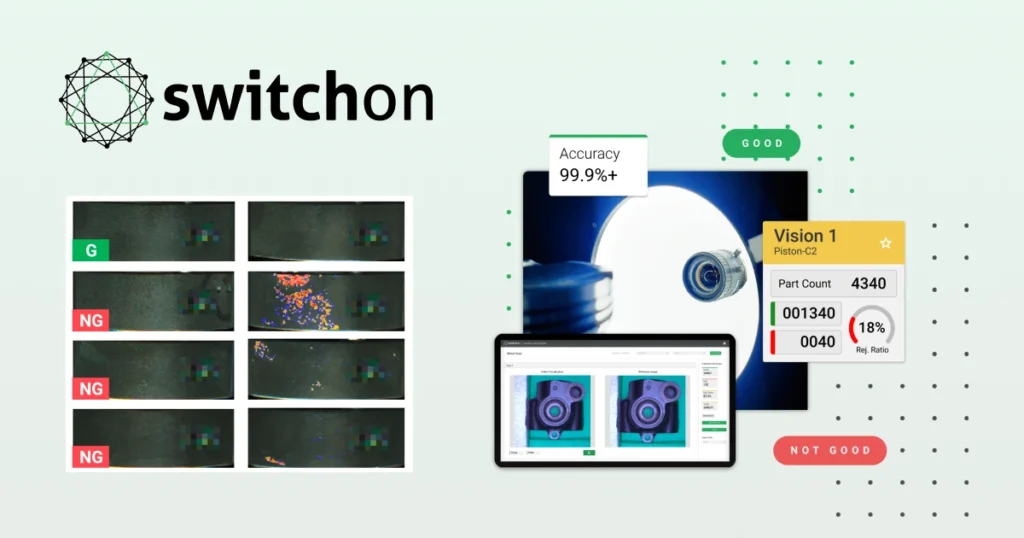

Enter SwitchOn’s flagship product, DeepInspect.

This AI-powered visual inspection system revolutionizes quality control by enabling manufacturers to train deep learning models using fewer than 200 high-quality images, without the need for any defect images.

This innovative approach drastically reduces the time and cost associated with deploying inspection systems, allowing companies to achieve production-level accuracy of over 99.9%.

Key Features of DeepInspect:

- Quick Training: With only 100 good images, manufacturers can achieve high accuracy within minutes, enabling rapid deployment across multiple product lines.

- High-Speed Inspection: DeepInspect supports high-speed manufacturing lines, inspecting up to 2,400 units per minute while ensuring near-perfect accuracy.

- Comprehensive Analysis: The platform provides detailed analytics and can be integrated with existing ERP and MES systems, giving manufacturers complete visibility over their production lines.

This unique capability allows industries to significantly reduce their quality costs by over 60% and attain 100% compliance with both internal and external quality standards.

Industries Impacted

SwitchOn’s technology is not limited to one sector, it spans various industries, including automotive, consumer goods, and pharmaceuticals.

1. Automotive Industry:

With applications in precision inspection, DeepInspect enables the flawless assessment of reflective metallic and plastic parts, such as bearings.

In environments filled with oil and grease, the system performs high-precision assembly and surface inspections, ensuring 100% compliance and reducing quality costs by over 50%.

2. Consumer Goods:

On high-speed production lines, the system can inspect soap bars and bottles for defects at a rate of 700 parts per minute.

This rapid inspection identifies foreign particles, cracks, and label defects with minimal setup, ensuring that only defect-free products reach the market.

3. Pharmaceuticals:

DeepInspect is critical for high-speed inspection of vials, tablets, and blister packs, detecting even the smallest surface imperfections that could jeopardize compliance or efficacy.

A Customer-Centric Approach

SwitchOn’s journey has been underpinned by a commitment to customer-centric innovation.

The founders adopted a philosophy inspired by Jeff Bezos: “Obsessive customer focus is by far the most protective of Day 1 vitality.”

This mantra drives the company to constantly seek feedback and understand the evolving needs of its customers.

The team at SwitchOn prides itself on its agility and responsiveness, continuously refining its products based on real-world applications and customer insights.

This customer-first mindset has proven to be a significant competitive advantage, positioning SwitchOn as a trusted partner for manufacturers seeking to enhance their quality assurance processes.

The Future of SwitchOn

As SwitchOn continues to grow, the company is poised to expand its market reach and enhance its technology offerings.

The founders are focused on scaling operations to support an increasing number of clients across the globe, aiming to streamline manufacturing processes further and contribute to the industry’s shift towards smart factories.

Moreover, the ongoing advancements in AI and machine learning present a wealth of opportunities for SwitchOn to innovate further, developing more sophisticated inspection systems capable of tackling even more complex defects across an array of manufacturing scenarios.